Machinary We Use

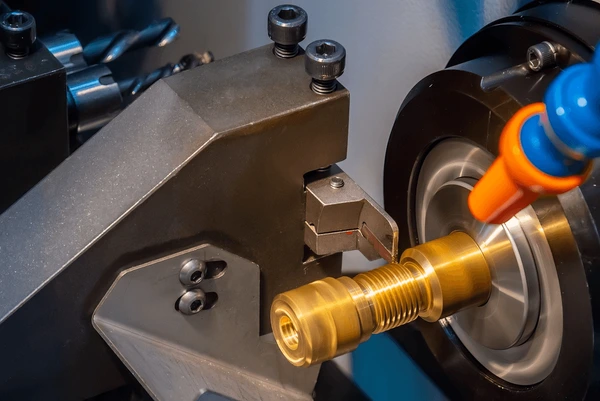

Machinery We Use for Manufacturing

Our manufacturing unit employs cutting-edge machinery to ensure precision and efficiency in brass component production. Key equipment are CNC Machining Centers, Die Casting Machines, Lathes and Milling Machines, Grinding Machines, Electroplating Equipment and Inspection and Testing Tools With this sophisticated machinery, we deliver high-quality brass components tailored to our clients' specific needs.

| Processing Material |

Brass & Special Copper Alloy Such as BS 2874 CZ 121, UNS 36000, BS 249, S.S. etc… |

| Machining Facility |

Bar Turning & Machining on Automatic Lathe Bar CNC Machining and Turning. VMC Machining. Forging + CNC Machining. Casting + CNC Machining. |

| Processing Expertise In |

Turned Engineering Component. Specialized Turned Components Automobile Turned Parts. Brass Sanitary Parts, PPR Fitting, Molding Inserts Brass Wire Terminals & Connectors Lighting & Earthling Protection Parts, Cable Gland Systems. |

| Additional Scope of Work | Complete Assemblies with Plastics and Rubber Parts. |

| Processing Range | 2 mm to 120 mm Diameter |

| Design Aid Software |

AutoCAD 3D, 3D Max Studio And Pro-Engineering |

| Documentation | PPAP Level -III |