Quality Assurance

Quality isn't a one-time effort; it's a consistent way of working.

At Aster Precision Industries, we are deeply committed to delivering the highest quality in all of our products. Every step of the manufacturing process, from sourcing raw materials to the final inspection of finished brass components, is meticulously overseen and evaluated through our comprehensive quality assurance program.

Our rigorous quality control measures, combined with our passion for innovation, ensure that every brass component reflects the strength, precision, and consistent excellence that define the legacy of Aster Precision Industries.

Quality Standard

Where Quality Meets Excellence

At Aster Precision Industries, our goal is to deliver products that meet international quality standards. We follow industry guidelines for product specifications and manufacturing processes to ensure top-tier quality in every item produced.

Our facility is equipped with both conventional and semi-automated high-tech machines and tools, along with a range of testing equipment to maintain product excellence. We are capable of manufacturing products that meet a variety of international standards and specifications, including ISO and those set by national standards bodies such as ANSI, DIN, JISC, BIS, NEN, SAC, SCC, SIS, SN, IS, SNV, SNZ, SABS, ABNT, DGN, IRAM, and KATS.

Our quality assurance team is both well-trained and experienced. To uphold the highest standards, our quality control team consistently monitors products and user requirements throughout the production process until final dispatch. With our rigorous quality control measures, we guarantee that customer needs are met with precision.

Measurement Tools

Equipment We Use

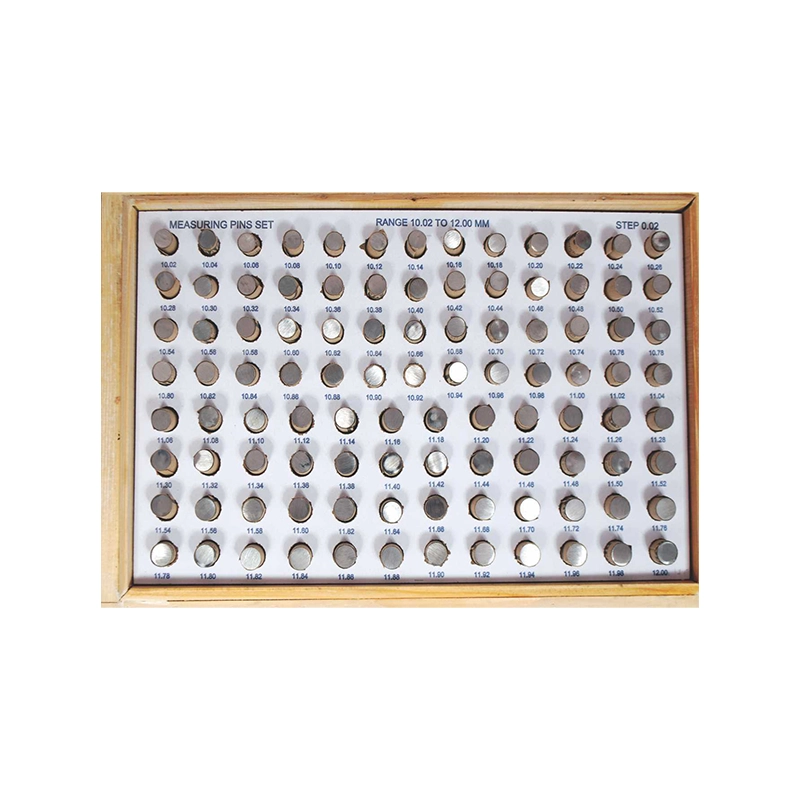

We continuously enhance and upgrade our instruments based on customer and component needs to guarantee the delivery of top-quality products

profile projector

Hardness Tester

Digital Micrometer

Digital Caliper

Digital Caliper For Inside And Outside Groove

Magnifying Lenses

Thread Plug & Ring Gauges

Plain Plug & Ring Gauges